| Posted By |

Discussion Topic:

KR Wilson dwell device

-- page:

1

2

|

|

supereal

supereal |

12-03-2011 @ 10:41 AM

12-03-2011 @ 10:41 AM

|

|

|

|

Senior

Posts: 6819

Joined: Oct 2009

|

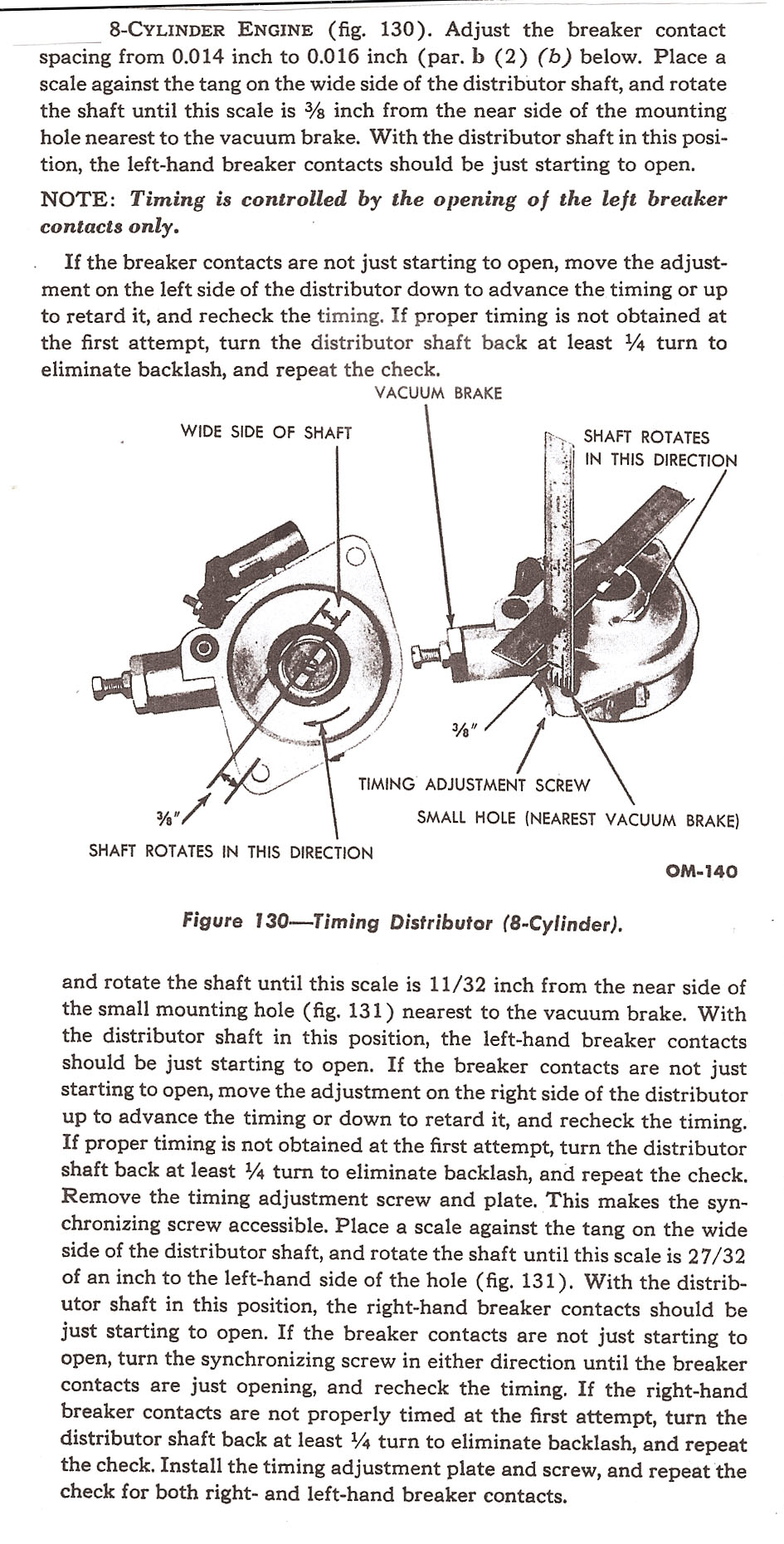

I am attaching the instructions for setting the timing. I use an ohmeter to determine exactly when the points just start to open. This method, while not as exact as on the machine, is close enough so you probably can't tell the difference. Connect the meter between the input terminal of the distributor and the body of the unit. I don't know how the points can be set with the distributor on the car, but removal isn't difficult. A dwell meter can tell you the reading when running, but the gap can't be changed without pulling the unit. I do agree with Tom that an ohmeter can't test the quality of the points. Many foreign made points have weak springs, poor threads and shorts in the brass bushing, as well as misaligned contacts. The strobe on the machine quickly shows if there is point "bounce" due to weak springs. Be sure that there is no discernable play between the shaft and the bushing in the body of the distributor. Any wear will cause the point gap, hence the dwell, to change.

|

239al

239al |

12-03-2011 @ 10:27 AM

12-03-2011 @ 10:27 AM

|

|

|

|

Member

Posts: 23

Joined: Oct 2009

|

TomO, I'm a little slow, I sure would appreciate it if you would explain how to set points, on the car, on a 1942-48 Ford using a dwell meter. Thanks.

|

TomO

TomO |

12-03-2011 @ 7:43 AM

12-03-2011 @ 7:43 AM

|

|

|

|

Senior

Posts: 7385

Joined: Oct 2009

|

The instructions for the 42 - 48 distributor are on Van Pelts web site.

http://www.vanpeltsales.com/FH_web/flathead_engines_distr-timing.htm

Be aware that a lot of the new point sets being sold today have weak springs and that cannot be determined with an ohm meter. Using the ohm meter procedure on used points can lead to timing problems.

The 42-48 points can be easily set with a dwell meter on the car.

Tom

This message was edited by TomO on 12-3-11 @ 7:48 AM

|

239al

239al |

12-02-2011 @ 7:29 PM

12-02-2011 @ 7:29 PM

|

|

|

|

Member

Posts: 23

Joined: Oct 2009

|

Supereal, If you can scan them, I would appreciate your instructions on how to set points using an ohmeter. Thanks.

|

kubes40

kubes40 |

11-30-2011 @ 7:26 AM

11-30-2011 @ 7:26 AM

|

|

|

|

Senior

Posts: 3577

Joined: Oct 2009

|

I can offer some 'real world' answers in regard to value as I have sold a number of these. The ones with the metal boxes bring more $ than the wood variety.

Restored (metal) units have consistently brought me

$650 - $800.

Unrestored units like the one you pictured bring about $275 - $350ish.

I hate to say it folks but eBay is 'real'. Like one fellow said, money in hand is what the value is...

Like it or not, it's a world economy now.

Mike Kubarth

|

kf5jsx

kf5jsx |

11-29-2011 @ 6:55 PM

11-29-2011 @ 6:55 PM

|

|

|

|

Member

Posts: 2

Joined: Nov 2011

|

Thank you to all those that replied. Every bit of information is helpful as I am not knowledgeable in this area. I am interested in selling it but I would need to find the right buyer. If anybody knows of someone looking for one, I would appreciate it if you send them my way.

Thanks again,

Jeffery

|

supereal

supereal |

11-24-2011 @ 9:57 AM

11-24-2011 @ 9:57 AM

|

|

|

|

Senior

Posts: 6819

Joined: Oct 2009

|

OK, guys. Happy Thanksgiving to you, too! It is interesting to note that there are now new machines being produced to do what the Sun and Heyers did, albeit at a rather steep cost. I don't get to many swap meets these days, but used to see Sun machines now and then. As for setting dwell, I've done it with an ohmeter many times. The important part is knowing exactly when the points open, and the meter will tell you that. You just need to have the rotor shaft in the right place. If anyone is interested, I'll scan the instructions. I wouldn't invest in a machine of any kind just to set distributors unless I did it often. Properly maintained, the old Ford distributor will go many miles, often as much as 10,000, between servicing. Anyone who really wants a machine should contact Bob Masters. He sells and services Sun, Allem Heyer, and others. He has repaired parts of ours. His e-mail is Rmasters3@fuse.net

This message was edited by supereal on 11-24-11 @ 9:58 AM

|

Stroker

Stroker |

11-24-2011 @ 9:08 AM

11-24-2011 @ 9:08 AM

|

|

|

|

Senior

Posts: 1460

Joined: Oct 2009

|

Alanwoodieman:

And a Happy Thanksgiving to you, and all the EV8 Tribe! Given your patternmaking skills,

maybe there is a market for a reproduction of the KRW device. I'm sure there are lots of

V8 folk who don't want to ship their distributor off just to set the points. With modern

automotive shops only equipped to deal with computer based systems, perhaps this could be

a "must-have" when the last Sun Machine cr*ps out, or the last Dr. Supereal forgets how

to run it. Would make a nice Christmas gift for the V8'er who has a 32-48 ignition to

maintain, or a nice loaner for RG's to offer their members.

You pointed out very nicely that very few of us have a local shop that would even have a clue how to set points, let alone dual points. Good Point!

|

alanwoodieman

alanwoodieman |

11-24-2011 @ 8:49 AM

11-24-2011 @ 8:49 AM

|

|

|

|

Senior

Posts: 873

Joined: Oct 2009

|

OK all you rich shop owning guys with the fancy tools give us back yard Ford guys a break. Owning one of these is better than having nothing, especially when no shops around us have the capability to set up our distributor and with a little practice a darn good job can be done with the KR Wilson box, ask the 10 or 15 guys around here that are riding around with the help of my KR Wilson box!! Superreal, I will take one of those cheaply purchased Sun machines next time you find one. Happy T-Day

|

Stroker

Stroker |

11-23-2011 @ 4:57 PM

11-23-2011 @ 4:57 PM

|

|

|

|

Senior

Posts: 1460

Joined: Oct 2009

|

I agree with Supereal regarding the usefulness of this tool. I had a Heyer Ford Test Machine

up until the 70's when I realized that my local machine shop's Sun machine would do the same thing without taking up space in MY shop. Probably the best thing about the Heyer was the comprehensive library of tune-up specifications that came with it.

The KRW fixture is an interesting conversation piece, and will probably delight an avid collector,

but is just not a "must-have" for someone just keeping their flatmotor humming.

Having said that, no one ever made a better rear hub puller than KRW, and we should be grateful that Winfield Tool Works, (437 W. Broadway Port Jefferson, NY 11777 516-928-3316)is still reproducing those.

This message was edited by Stroker on 11-23-11 @ 5:19 PM

|

Reply to Discussion

Reply to Discussion

supereal

supereal