| Posted By |

Discussion Topic:

clutch chatter

-- page:

1

2

|

|

supereal

supereal |

03-25-2011 @ 10:23 AM

03-25-2011 @ 10:23 AM

|

|

|

|

Senior

Posts: 6819

Joined: Oct 2009

|

While the "slingshot" does restrain the fore and aft movement of the engine and transmission, it doesn't dampen the twisting of these components on their horizontal axis as power is applied. A better solution would probably be a lateral extension of the motor mounts to provide increased leverage, particularly at the rear. Early rear mounts were identical to the front rubber "donuts", and were replaced by the rubber ring type in later models. All mount designs were tempered by the need to isolate engine vibrations, making rigidity a trade off. If there are better ideas, they haven't emerged to date.

|

okydoky

okydoky |

03-25-2011 @ 9:22 AM

03-25-2011 @ 9:22 AM

|

|

|

|

Member

Posts: 11

Joined: Jul 2010

|

Thanks guys for responding in such a timely manner. I would like some more input on the so-called slingshot. I am intrigued with this idea but would like to hear from some folks with some experience with this device before I pay somebody to fabricate it for me.

|

supereal

supereal |

03-20-2011 @ 10:18 AM

03-20-2011 @ 10:18 AM

|

|

|

|

Senior

Posts: 6819

Joined: Oct 2009

|

One approach that I didn't include in my previous post is that sometimes the chatter, particularly if severe, can be reduced by placing the car on sturdy stands with all four wheels off the ground, then loosening the bolts that attach the transmission to the engine. After starting the engine and placing the transmission in gear, let it run a bit, work the clutch a few times, then cinch down the bolts. This will often reduce any mismatch between the center line of the transmission and the pilot bearing in the flywheel. Just be very careful when working under a car on stands, particularly when it is running. I prefer to do it with the car on a hoist in the shop, of course.

|

Stroker

Stroker |

03-19-2011 @ 8:09 PM

03-19-2011 @ 8:09 PM

|

|

|

|

Senior

Posts: 1460

Joined: Oct 2009

|

When I first started driving the family's 38 Station Wagon in 1954, I just sort of learned to deal with it by experimenting with throttle and clutch. The problem was much worse in reverse, but could be tamed by appropriate engagement. At this point, the car had lost its' anti-chatter rods due to several engine change-outs. I drove this car through college, until the mid-60's, and didn't drive it again until the late 70's, after I had replaced all the motor mounts, new motor, clutch, flywheel, and installed a pair of NOS anti-chatter rods. Guess what?

I will say that the anti-chatter rods do look nice, and they fill the holes in the bell housing very

appropriately. My biggest problem was finding those counter-sunk square-drive bolts for the frame end. In my latest refurbishing of the "o'l family bus", I plan on leaving the "rods", and teaching the grandchildren how to properly engage a really fussy clutch...It will be good for them.

|

oldford2

oldford2 |

03-19-2011 @ 6:57 PM

03-19-2011 @ 6:57 PM

|

|

|

|

Member

Posts: 275

Joined: Oct 2009

|

When we first got our mostly original 43,000 mile 46 sedan the clutch chattered. So, did all the things to lessen the chatter. New front and rear motor mounts, rear spring shackles,added chatter rods, etc., etc..

I noticed when my wife drove it, it did not chatter much. I think she was slipping the clutch. Anyway, we have learned to operate the clutch now to minimize to zero chatter. So, part of reducing chatter is learning driver clutch engagement. John

This message was edited by oldford2 on 3-19-11 @ 6:57 PM

|

42wagon

42wagon |

03-19-2011 @ 12:54 PM

03-19-2011 @ 12:54 PM

|

|

|

|

Senior

Posts: 586

Joined: Oct 2009

|

supereal

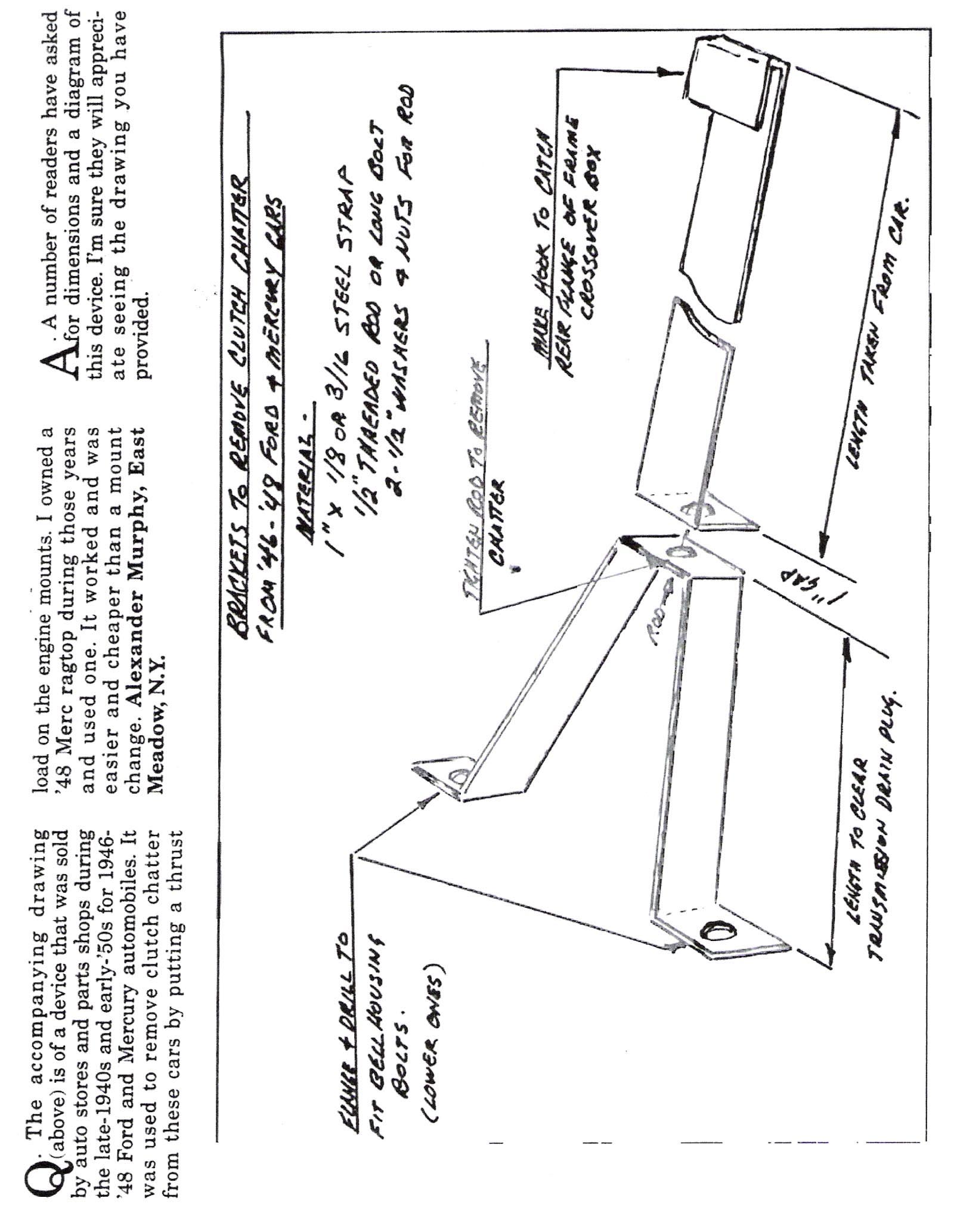

That gadget you supplied a sketch of is known around here as "the slingshot". I have one that came on my wagon. Don't know if it was an aftermarket accessory or something a local garage made up. Doesn't seem to do much good but is a great conversation starter.

42 wagon

|

supereal

supereal |

03-19-2011 @ 10:53 AM

03-19-2011 @ 10:53 AM

|

|

|

|

Senior

Posts: 6819

Joined: Oct 2009

|

I agree with 42. All of the old Fords I've owned had some clutch chatter, some more than others. The Ford drive line went basically unchanged from the beginning thru 1948, mostly due to Henry's rigid opposition to change. As said, the problem arises as the rear axle pushes forward on the torque tube, leaving the motor mounts to absorb the thrust. It is tempting to blame the clutch, itself, for the problem, but there are other factors to consider. The rear spring must be intact, with clips in place, and firmly attached to the crossmember. The spring shackles must have pins with little or no play. The rear hubs must be tight on the tapers. If you hear a "clunk" as you drive, check them. The u-joint housing must be tightened over the ball, with the cork seals in place. Lastly, the clutch release linkage and clutch housing bushings must be free of play. One end is attached to the frame, with the other end at the release shaft thru the bell housing. Any movement of the drive train is magnified by the linkage. The arm on the release shaft moves a fraction of the pedal travel, and as the engine moves on its mounts, this is translated into an irregular operation of the pressure plate, causing much of the "shudder". Lots of remedies have been tried. I've attached one such. None will remove all the problem, but you can reduce it to a tolerable level.

|

TomO

TomO |

03-19-2011 @ 8:45 AM

03-19-2011 @ 8:45 AM

|

|

|

|

Senior

Posts: 7385

Joined: Oct 2009

|

A fast idle or too much gas when engaging the clutch, will add to clutch chatter.

The idle should be between 450 RPM and 550 RPM, preferably at 450 RPM.

When starting out, let out on the clutch until the engine starts to slow down, then increase the amount of gas as you let the clutch out the rest of the way.

Tom

|

42wagon

42wagon |

03-19-2011 @ 4:10 AM

03-19-2011 @ 4:10 AM

|

|

|

|

Senior

Posts: 586

Joined: Oct 2009

|

Clutch chatter is something that Henry's engineers never were able to entirely eliminate from our beloved old Ford's. At some point they determined that the anti-chatter rods were not the answer and stopped putting them in.

That said I don't believe you have addressed the heart of the problem. The problem seems to be caused by the drive train shifting back and forth when the car is first put in gear,I would check to see that your motor mounts are as tight as you can possibly get them . Also the bolts at the yoke that supports the end of the transmission. After that check all the connections between the rear axle and the frame. Is there play in your universal joint?

You may reduce the problem but I don't think it will ever totally go away.

Ted

|

51f1

51f1 |

03-18-2011 @ 10:32 PM

03-18-2011 @ 10:32 PM

|

|

|

|

Senior

Posts: 573

Joined: Oct 2009

|

Perhaps as 37RAGTOPMAN says, it needs to wear-in a bit. I had some chatter on my restored truck. I have a like-new pressure plate, a resurfaced flywheel and a new disc and throw-out. After about 3,000 miles it has improved quite a bit. If it doesn't wear-in, you need to carefully check each component. The pressure plate could be adjusted improperly or the flywheel surface may not be true. You may have a bum disk. Check to be sure the transmission is lined-up properly with the engine.

Richard

|

Reply to Discussion

Reply to Discussion

supereal

supereal